Boiler House Risk Assessment

These Regulations which amended S.I. No. 299 of 2007, came into operation on 1st January 2013. The Regulations included a new Part 10 and Schedule 12 to the Regulations relating to Pressure Systems. It is a requirement to conduct a risk assessments.

Rackard Steam + Biomass Services risk assessments are practical and effective.

Boiler Gas Side Explosion Paris Tennessee June 2007

Main causes of boiler accidents

- Improper maintenance

- Lack of operational procedures for boilers

- Incorrect removal and replacement of parts

- Lack of proper training

The leading cause of boiler failure is poor water management followed by fuel system failures.

There is growing industry concern over boiler house manning levels and the over reliance on outdated boiler instrumentation and controls.

Verifying the correct level of boiler instrumentation for the current level of manning is an essential part of a risk assessment.

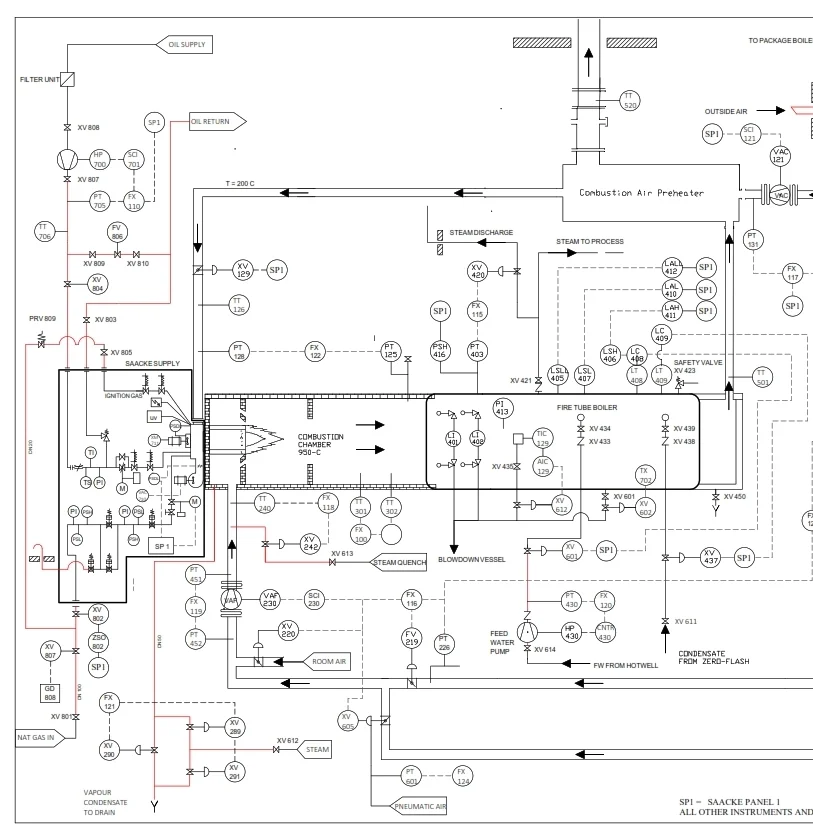

P&ID of Babcock Wilson Thermal Oxidizer

A Boiler House Technical Risk Assessment

The collaborative approach covers much more than slips, trips and falls. It covers the 5 steps to risk assessment.

- Identify the Hazards

- Decide who might be harmed and how

- Evaluate the risks and decide on precautions

- Record the findings and implement them.

Those operating and managing a system know it best. Stakeholder buy in is achieved by collaboration ensuring safe and cost effective boiler operation.

Improve pressure availability & steam quality

Commercial Benefits

Experience has shown that collaborative focus on the boiler house operation leads to improvements in.

- Operational efficiency

- Boiler availability

- Energy savings

- Reduced maintenace costs

T.

The General Application (Amendment) Regulations 2012 are made under the Safety, Health and Welfare at Work Act 2005 (No. 10 of 2005) which is referred to in this guide as the “2005 Act”.

The penalties for breaches of health and safety legislation are;

Up to €5,000 per charge and/or up to twelve months imprisonment in the District Court

Up to €3,000,000 and/or imprisonment for a term not exceeding two years in the Circuit Court